Our leading geopolymer laboratory in Europe produces material solutions for the needs of the low-carbon concrete and waste sector. We analyze and tailor material mixes based on the customer’s own raw materials and help with the implementation of ready-made mixes.

Start low-carbon concrete production

About 80–90% of concrete emissions come from cement used as a binder, the production of which produces up to 7–8% of the world’s greenhouse gas emissions.

From the beginning of 2026, the climate assessment required for new buildings and the upper limit for the carbon footprint, below which a building permit is required, are leading towards low-carbon concrete construction. It is time to make low-carbon a part of our own production.

Geopolymers to replace cement

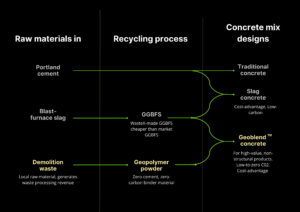

Concrete’s carbon dioxide emissions can be significantly reduced with geopolymer technology. Geopolymers refer to various mineral-based materials, either obtained from soil or industrial side streams, that are able to bind aggregates into a concrete-like material, similar to cement. In our case, these minerals are processed from demolition waste, and this sets us apart from our competitors. When cement, the binder of concrete, is replaced with a waste-based binder, a concrete-like material is created that has a carbon footprint of up to -85% lower than concrete.

When cement is replaced with powder made from construction and demolition waste, the result is:

CO2 emissions

lower binder costs

binder options

EPD-certified mass

An Environmental Product Declaration (EPD) is a standardized way of presenting the environmental impacts of a product during its life cycle based on a life cycle assessment.

Our Geoblend mass is EPD-certified in 2024 and a proven low-emission (-85% CO2) alternative for concrete construction.

View the EPD certificate below

A new era of binders

The binder market is built on generic alternatives. We are introducing a new dimension to the market that significantly expands the range of binders.

Increase security of supply and self-sufficiency by expanding your binder range and differentiate yourself from your competitors by manufacturing end products based on recycled materials!

Performance comparison

Traditional concrete (Portland)

Slag concrete (GGBFS + Portland)

Geoblend (Geopolymer + GGBFS)

Product CO2

Bending strenght (28 days)

Compressive strength (28 days)

Product net cost (2025)

Product net cost (2030)